By Bill Bregar

SENIOR STAFF REPORTER

Published: October 27, 2014 6:00 am ET

Updated: October 27, 2014 12:15 pm ET

Image By: Caroline Seidel

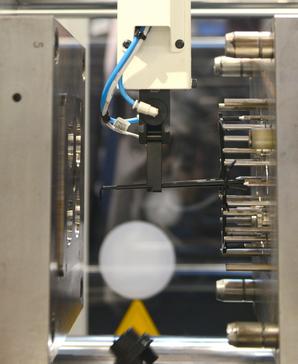

A telescoping sprue picker robot works in a newly redesigned CX injection molding machine at the KraussMaffei booth.

FRIEDRICHSHAFEN, GERMANY — KraussMaffei Technologies GmbH targeted small-tonnage machines at Fakuma 2014 — including the rollout of its reworked CX press, boasting lower energy use, and a space-saving design.

KraussMaffei also rolled out its new Adaptive Process Control system (APC) that adjusts the changeover point from injection to pack-and-hold, and the holding pressure during the show in Friedrichshafen.

KM’s sister company Netstal-Maschinen AG is demonstrating high-speed molding of thin-wall medical and packaging.

Hans Ulrich Golz, president of injection molding machinery at the KraussMaffei Group, said innovations made to the CX machine make it operate 15 percent faster, use 10 percent less energy and run 30 percent quieter.

A new telescoping sprue picker is designed for plants with low ceilings. The robot is completely integrated into the machine’s protective enclosure.

Three CX presses are running at KraussMaffei’s stand, molding a small crown wheel gear; a two-component key fob, with electronics molded into the part; and a two-component fan setting wheel.

Two AX presses also are on display, molding a container for soap sticks and a MuCell foamed cover for appliances.

Golz said KM is now making the all-electric AX’s in larger sizes — 450-tonnes and 550-tonnes.

KM officials are calling the APC machine function “cruise control” because it compensates for fluctuations in the injection molding process. APC is included on all KM machines. The technology adapts to changes in machinery functions or difficult raw materials, such as mixtures that include recycled plastic.

The “get small” theme extends to KM’s polyurethane processing machinery. At Fakuma, the company is introducing its smallest PUR metering machine, the new EcoStar 8/8 with a pump output of eight liters per minute. The machine uses a new Siemens KTP 400 control system with a touch screen display. KM is targeting the EcoStar 8/8 for smaller foamed parts such as automotive arm rests and small insulating pads for soundproofing in cars.

KM also is introducing the thermoplastic resin transfer molding process to produce a car’s B-pillar reinforcement, dubbed T-RTM. The machinery maker is working to develop the process with Volkswagen AG and BASF SE.

The use of a thermoplastic matrix of nylon, instead of thermosets, reduces costs, cuts weight by 30 percent, allows mass production and permits recycling, KM said.

Netstal is molding ultra-light polystyrene petri dishes in an eight-by-eight cavity mold made by Schottli AG. The cycle time is 3.7 seconds.

Another Netstal press is a polypropylene, rectangular food container molded with in-mold labeling, on a 4.9-second cycle.

|